The information in this article was provided by Gilba Solutions

One of the perpetual debates in the turf and amenity industry with selecting a fertilizer is whether granulated homogenous fertilizers give a more accurate application at a prescribed rate than blends of similar analysis.

What is involved in manufacturing a fertilizer in the turf industry is seldom understood. However, several factors should be considered to ensure the result is a product that meets certain quality and analysis. From both an agronomic and handling perspective the physical nature of a Fertilizer is important. Issues such as “caking”, dust content, and poor particle distribution must be addressed to produce a free-flowing product that is dust free and stable under a range of humidities.

The importance of Particle size in selecting a fertilizer.

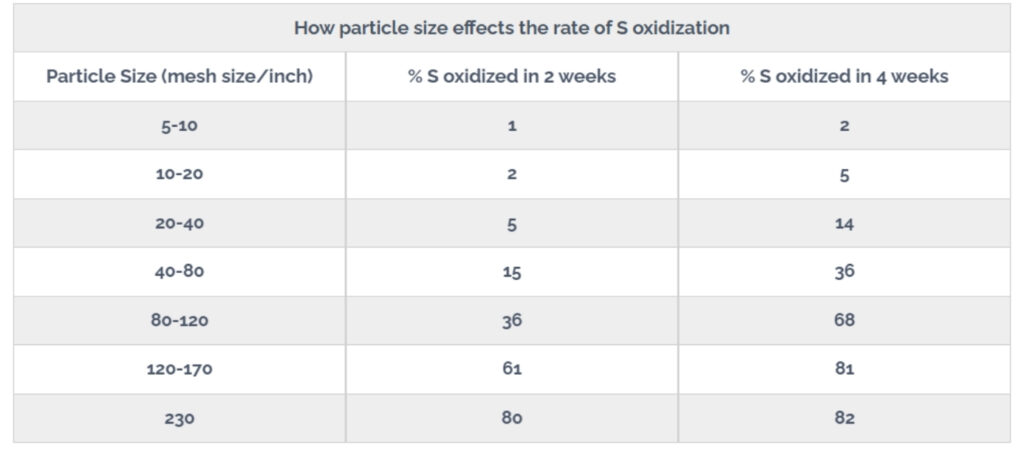

Particle size is important as it directly influences where you can use a product. For example, a large granule cannot be I used no find cut greens turf. Firstly it impacts ball roll and secondly, the vast majority will be removed and therefore wasted when mowing is carried out. Products having a low degree of water solubility should be applied in as small a size as possible so that plants can use them. For example, bulk blended Fertilizer generally has a mesh size of 5-15 and so a Sulphur granule of this size takes several weeks to oxidize to SO4. In the case of lime (not granulated) research has shown that coarse line is in effect relatively ineffective. This contradicts a commonly held belief that a coarser granule gives a longer-term benefit because it dissolves more slowly. From a blending perspective, particle size is also important as you are aiming for a high degree of product uniformity. Particles being blended should agree in both their upper and lower limits but also be similar in size between these limits.

Granule hardness.

Particles should be hard enough to cope with normal handling without fracturing. Examination of an homogenous fertilizer will always show little particle variation but they are not identical. Good granulation requires a degree of sophistication, engineering, and temperature control that only a few manufacturers have. A study by Karnock (1986) showed that there was little difference in the rate of applied nutrients between quality blended fertilizers and homogenous products

The use of fillers in selecting a fertilizer

Fillers are used to lower the production cost of a Fertilizer and can be anything from limestone chip to bentonite. They act merely as a means of providing weight. The easiest way of determining how much filler a Fertilizer contains is to ask for a print out of the formulation sheet that contains the formula for manufacturing this product.

This is a fact worth considering. Simple maths also shows that If the fertilizer only contains 30% slow release, it is impossible to have an even distribution of the slow release granules over the treated area. Bearing this in mind anything less than 65% slow release should raise questions as to how well the product performs agronomically. Less than 65% and it is difficult to see how you can have sufficient particle distribution to get an even turfgrass response.

Segregation properties

When handling fertilizers non-uniformity also referred to as “segregation” can occur. This is an important characteristic to be aware of as it impacts the performance of the product.

Segregation occurs when individual granules possess differing physical properties to each other. This can occur to such an extent that they respond differently when the product undergoes mechanical handling. Particles having similar properties tend to congregate and the homogeneity of the mix is lost.

Particle size has the largest influence on the likelihood of this occurring and neither the shape or density has such a large influence. If all the particles have the same chemical composition but differ in size, handling will result in physical segregation but will not affect chemical uniformity.

In contrast, with poor granulation, small particles can differ in composition from larger ones. This results in segregation. Solutions to avoid this are better granulation or screening to narrower size ranges.

The information in this article was provided by Gilba Solutions