Biodiversity and sustainability have been a hot topic in the greenkeeping and grounds management industry for several years now, but it’s never been more relevant than now. There’s a rapidly growing interest in taking a sustainable approach to grounds management, which begs the question: what can be done to implement sustainable management? We spoke to Kersten UK to see how the site maintenance equipment company is taking steps towards more sustainable practices this year.

Q: Can you provide an overview of Kersten UK’s approach to sustainable land management and how it aligns with reducing pesticide use?

At Kersten, the most fundamental principle is that Prevention is better than Cure. We have identified three core ideas that help us to best manage surfaces, whilst keeping remedial action (such as pesticide use) to a minimum. Firstly we must understand that no surface is “maintenance free”. All surfaces perform a set of functions, which can be inhibited by different factors, such as detritus build up, surface displacement and surface compaction. This can lead to flooding, potholes, weeds and all manner of other problems, which are symptoms of these primary issues. All these issues can be prevented with maintenance.

Secondly, we need to work with natural processes. Understanding processes, such as the soil cycle, and the plant life cycle, as well as seasonal changes allows us to take advantage of these processes and intervene at the most effective times to prevent weeds, with the least effort and maximum benefit.

Thirdly, we must consider not only the managed surfaces themselves, but the natural environment around them. This can help us reduce excess detritus build up, or other problems that are influenced by the surrounding environment.

Plant choices and different types of barriers can have a large impact on the maintenance of surfaces adjacent to them.

Q: What are some of the main challenges associated with traditional pesticide-dependent weed control methods, and how does mechanical weed control address these challenges?

There are several challenges with using pesticide dependent weed control methods, that can be overcome by a preventative approach and mechanical control. The first is partly a problem with defining the problem.

Plants don’t grow in hard surfaces, they grow in the soil that builds up on the hard surface. Killing a weed with pesticides on a hard surface does not really help the overall situation, as the dead weed will add more soil to the surface as it decomposes, providing an ever-increasing bed of nutrients for the next weed to take hold.

This soil is a problem for several reasons. The deeper it gets, the more favourable the conditions become for stronger and more fervent types of perennial plants that can start to damage the surface with their roots.

Soil also traps moisture, preventing the surface from drying out. Over winter, this has the potential to freeze, exposing any weaknesses in the surface and often creating freeze-thaw damage. Both of these issues can be better solved by removing the soil (along with the weeds) rather than just killing the weeds.

Aside from this, many hard surfaces are designed to allow water to run off into drains and eventually often end up in our rivers, or reservoirs. It is therefore important to avoid spraying on these surfaces as much as possible, especially close to drains, as we don’t want these chemicals in our water. Using a mechanical approach will prevent this.

Q: Could you explain how Kersten UK’s mechanical weed control solutions work, particularly on hard-standing surfaces?

Kersten supply a range of tools for managing weeds on hard surfaces:

- Sweepers: By removing the detritus with sweepers, we can prevent it from decomposing into soil. This is the first line of interference we can use to prevent weeds. If they have no soil to grow in, they will not emerge.

- Weedbrushes: These can remove the soil buildup when it becomes too heavy for a sweeper. This can be more of a remedial action and allows us to clean the surface back to back.

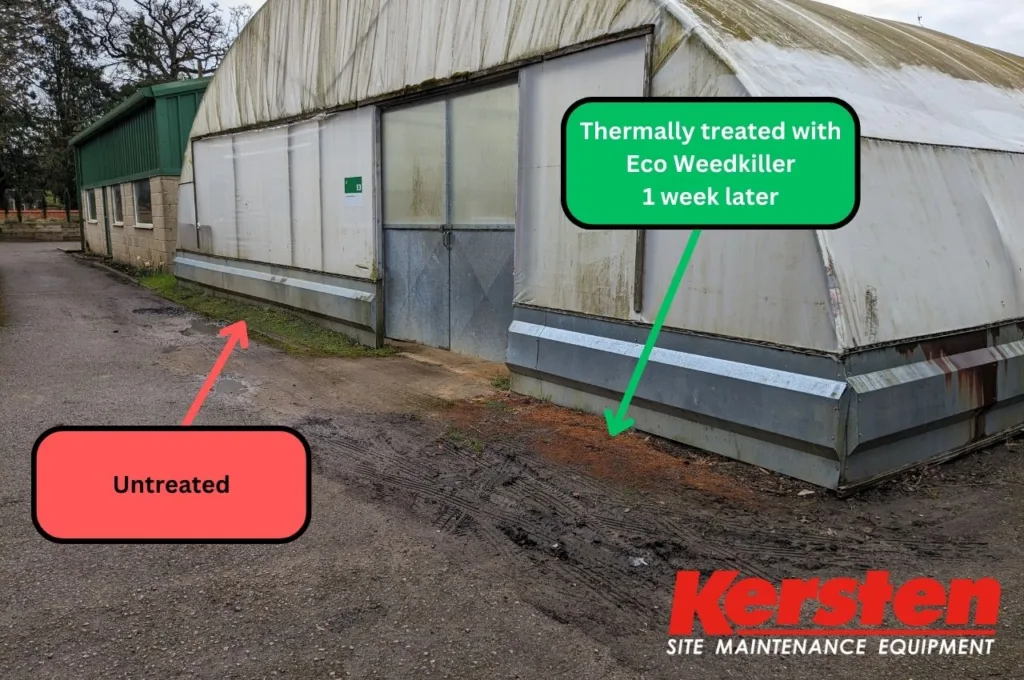

- Thermal tools: These can also be considered mechanical. We have different options using either hot air or hot water to kill weeds. Heat can be used to destroy the chloroplast in the leaves and stem of a plant, collapsing its structure and rendering it incapable of photosynthesis. Different methods will be suitable for different types of plants and on different surfaces.

Q. What types of machinery or equipment does Kersten UK offer for mechanical weed control, and how do they differ from traditional pesticide applications in terms of effectiveness and environmental impact?

In terms of controlling weeds, we can do this in several ways as discussed above.

My preferred option is always to remove the soil where possible with a weedbrush. This not only removes the weeds but also helps solve other problems, such as drainage, and prevents freeze-thaw damage. We offer a range of different weed brushes, either on two-wheel tractors or ride-on tractors, depending on how much soil needs to be removed.

Hot air is effective on annual plants and moss, and can be used to kill perennials with repeated applications that deplete the energy stored in the root system. They are generally much quicker to use than hot water systems, but may require more treatments.

Hot water is a more potent form of thermal weeding system because the water can penetrate the soil, allowing it to cook the roots of the plant as well as the stem and leaves. This allows fewer treatments across a year than with hot air. However, it is generally a slower process.

The environmental impact of all these methods depends on a lot of factors, especially the time in a plant’s lifecycle the treatment is carried out. The earlier you treat a plant with heat, the less energy will be needed to kill the weed. The impact of the tool being used is far outweighed by the difference in the weed burden being treated.

If we can reduce the weed burden by reducing the amount of soil weeds have to occupy, and by treating as early in their lifecycle as possible, we can minimise the amount of treatment we use. This applies to pesticides too, although pesticides usually require more foliage, and therefore must be applied later in the growing season.

Q. In what ways can mechanical weed control contribute to long-term sustainability and environmental preservation compared to chemical-based approaches?

Mechanical treatments contribute to the ability of the surface to perform its functions. They help to significantly extend the working life of the surface, ensure it drains properly, provides access, grip, and support for traffic and pedestrians.

Weed killing using chemical pesticides only kills the weeds and does not treat any of these problems, leaving the surface more susceptible to damage from freeze-thaw, plant roots, flooding, and other issues, costing much more to fix in the long run. The re-construction of a surface is many times more expensive to the environment than its maintenance; therefore, extending the life of the surface is paramount to sustainability.

Q. Are there any specific industries or sectors where mechanical weed control has shown particular success, and what are some notable case studies or examples?

A successful approach can be found for any scale of site. We have success stories in private tennis courts all the way up to cities.

A particular example I would bring to people’s attention is Hull City Council, who are using our pedestrian weed brushes in conjunction with other equipment as part of their “Love Your Neighbourhood” Campaign. The project aims to make a visible improvement to what people see when they step outside their front door, focusing on things such as:

- Litter bin repairs/replacement

- Graffiti removal

- Fly-tip clearance

- Bulky item clearance

- Verge edging

- Grass cutting

- Shrub maintenance

- Leaf removal

- Hedge cutting

- Gully cleaning

- Pothole repairs

- Street light repairs

The project was introduced in 2023 and there has been a lot of positive feedback. Councilor Mike Ross said:

“The trials we have carried out so far have been very successful, with residents telling us how happy they are with the difference the clean-ups have made.”

Our machines have been utilised to great effect throughout the city for path edging and weed management.

Q. How does the cost-effectiveness of mechanical weed control compare to traditional pesticide use, both in the short term and over time?

In the short term, alternatives will be more expensive than using pesticides, but as we’ve Discussed, they are doing quite different things and I would argue that simply using chemicals isn’t achieving the necessary maintenance of the surface to prevent damage. The majority of the cost of the mechanical treatments is in the upfront equipment costs and in clearing years of neglected soil build-up. The following years will require far less intervention to keep the surface in good condition and with low levels of weeds.

We are starting to collaborate on some research into the longer-term costs and potential savings to be made by implementing Integrated Weed Management techniques on hard surfaces. So far, research has only shown the sustainability of a few single alternatives in isolation across a very short time scale, and without altering things like treatment timings to account for product differences.

Once the research has been done, I can offer a better answer, but for now, common sense indicates that maintaining a surface with brushes reduces the weed burden and extends the life of the surface, greatly reducing the cost of any further applications of thermal or chemical control and spreading the cost of the surface installation over an extended period.

Q. What kind of training or expertise is required for implementing mechanical weed control solutions effectively, and does Kersten UK offer support in this regard?

No formal certification is required for implementing a mechanical weed control solution; however, a fundamental knowledge of Integrated Weed Management can significantly enhance your results. I would recommend Lantra’s Awareness of Integrated Weed Management course, which we helped put together, but we can also assist with quite a few resources on our website to help understand the basics.

Q. How do you see the future of weed control evolving, and what role do you envision mechanical methods playing in that future?

The ultimate solution requires people’s knowledge to be updated. The tools to do the job effectively are already here, but people tend to try and fit them into the way they currently do things instead of adapting their approach to suit the tools.

Q. Finally, what advice would you give to businesses or organisations looking to transition away from pesticide-dependent weed control methods and embrace more sustainable alternatives like mechanical weed control?

My best advice would be to survey your site. A survey should identify the sources of detritus, the current state of surfaces, and what needs to be done to bring it back to a suitable state that is easy to maintain.

Only then can you really create a plan and put an effective regime in place. If you simply swap chemical pesticides for another product in your current weeding regime, you will always be on the back foot and spend a lot more time and money than you need to.

We’d like to thank Sean Faulkner at Kersten UK for taking the time to discuss sustainable management in such detail, and we hope you learned something valuable from this article.

You can visit Kersten online at kerstenuk.com